Leveraging Microsoft’s global customer project implementation experience, IMCP aims at empowering Chinese enterprise’s transformation.

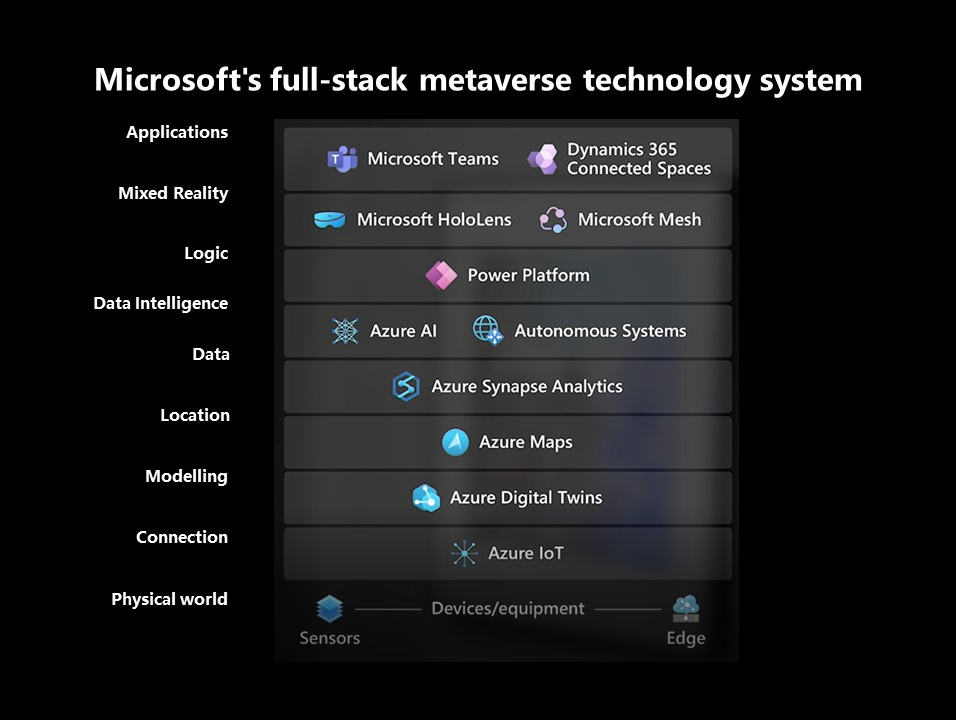

With the help of Microsoft's full-stack technology system, IMCP is designed to help enterprises achieve digitization and intelligence, and ultimately help them stay competitive in the market.

In recent years, how to ensure the efficient and correct operation of complex production process, improve production efficiency, reduce cost, and accelerate transformation has become the focus of manufacturing enterprises. With the four essential features of its own industrial metaverse of replicate with digital twins, automate and control, integrated data and AI, and visualize with immersivity, Microsoft can help users realize the robotic arm twins in the cloud and understand the production status of robotic arms in real time; analyze and investigate issues through AI and MR, as well as contact experts remotely to quickly solve production line issues.

To Microsoft, the core of the Metaverse is to connect people, things, places, and business processes in production, work, and business activities in the real and digital worlds in a lasting and seamless way. With the metaverse, we can replicate and reproduce various elements in the real world, develop and validate more efficient and intelligent operational and management solutions within the digital environment, create a refreshing interactive experience, and thus uncover more unprecedented application scenarios and business values.

Industrial Metaverse Successful Cases

One of the world's largest brewer, is using Azure Digital Twins to build a digital model of its brewery and supply chain, enabling brewers to brew high-quality beer and front-line operators to remotely monitor quality and traceable data during production.

A leading industrial enterprise in the world is building its Integrated Asset Performance Management (IAPM) solution that takes Azure Digital Twins as the core technology to show how rotating machinery such as turbines and motors are maintained, which ensures efficient operation while being cost-optimal.

A global leader in industrial robotics, is building digital environments for robotics, leveraging technologies such as Microsoft Azure IoT and Azure Digital Twins that enable collaboration and robotic teleoperation in the Industrial Metaverse.

One of the world's leading motor group is building an electric vehicle battery asset management platform on Azure Digital Twins to improve battery management efficiency.

Key Functions and Typical Scenarios

The "Industrial Metaverse" solution by Microsoft, which integrates a range of Microsoft Intelligent Cloud services with innovative technologies that are already in operation in the Chinese market.

IoT and Edge Device Connectivity Management

With Azure IoT services, thousands of various devices and sensors in production of factories lines and supply chains of enterprises can be interconnected to collect and summarize various data information in real time. Azure Stack HCI and Azure Arc provide 24/7 intelligent services in edge and offline environments, which facilitates and unifies the management of cloud resources across cloud, edge and hybrid deployments.

Building Digital Twins and Discovering Data Intelligence

Azure Digital Twins enables enterprises to build digital twins models of people, objects, fields, and processes in the digital world; Azure data platform helps break through data barriers within industrial enterprises and performs efficient data analysis to gain intuitive insights; Azure Machine Learning enables enterprises to train data models, simulate factory operations, and perform predictive maintenance on equipment.

Virtual-reality Human-computer Experience and Business Integration

Based on Microsoft Azure's comprehensive capabilities ranging from Azure AI, IoT, to Data, HoloLens, mixed reality human-computer interaction experience can be created to provide front-line employees with virtual-reality operation guidance and technical support. Factory's existing production environment and business processes can be seamlessly integrated through Microsoft Teams and Dynamics 365 business applications. With the Power Platform low-code development platform, more flexible and efficient application development and business innovation can be low-hung fruit.

Industrial Metaverse Co-innovation Program Offerings

Envisioning

By visiting Microsoft AI and IoT Insider Lab's project demos, you will gain an in-depth understanding of Microsoft's Metauniverse methodology, technology stack, best practices, etc., to further explore the IMCP validation plans and scenarios.

Ideation

Complete your project validation PoC development within maximum two weeks, under the assistance of the technicians from Microsoft AI and IoT Insider Lab.

Project implementation

Jointly accelerate the commercialization of PoC/MVP with Microsoft Azure's comprehensive Metaverse technology stack and ecological resources. Demonstration opportunities at Microsoft AI and IoT Insider Lab are open to excellent projects.

If enterprises have further needs for PoC projects, we can dock Microsoft partners to land MVPs. ECIF(End-Customer Investment Funding) can provided up to 1:10 ROI support according to your needs.

Criteria

- The goal of your project is to build innovative Industrial Metaverse products/solutions, including but not limited to remote operations and maintenance, predictive maintenance, artificial intelligence, digital twins, dark factory.

- Your project has used or is planning to use Microsoft AI or IoT technology and plans to go commercialization within 6 months with clear business and technical needs. You will consume your own Azure subscription during the IMCP.

- Your project has been endorsed by your internal management, and has inhouse or outsourced R&D team.

- Willing to sign agreement and NDA with Microsoft AI and IoT Insider Lab at PoC phase.

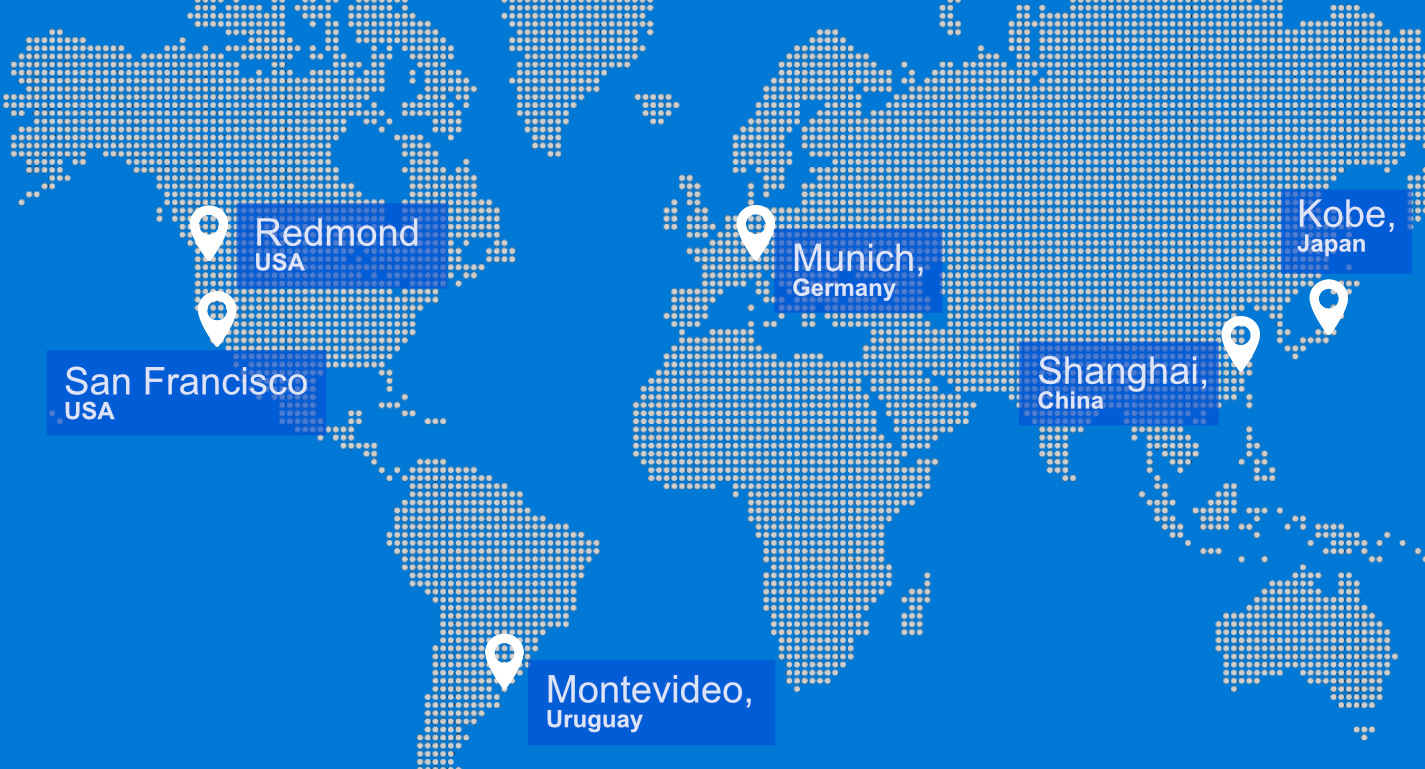

Lab Locations

Microsoft AI Co-Innovation Labs are located in Redmond, USA, at the heart of Microsoft’s product group expertise; San Francisco, the world's important high-tech research and development base; Munich, Germany, a hub for European partners; Kobe, Japan, the important international trade port and industrial city, and Montevideo, Uruguay, a hub for Latin American partners. Meanwhile, the online technology support of labs is available for anyone in anywhere on this planet.

Microsoft AI Co-Innovation Labs offer you access and facilities to build, develop, prototype, and test your solutions for your market.

Our Microsoft technology experts are here to help

Program Managers

AI Engineers

Cloud Engineers

Software Engineers

Electrical Engineers